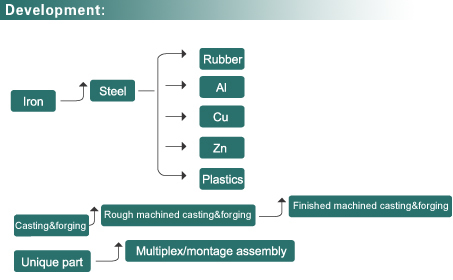

Optimized process and material guarantee the consistency of quality and economics from the pre-scheming. We have gained abundant experience in processes such as sand casting, investment casting, centrifugal casting, forging, welding, stamping on material covering iron, stainless steel, carbon steel, steel alloy, aluminum alloy and rubber etc.

3D Model Engineering Analysis, CNC Lathe Tooling and Machining, Process-Founded Accessory to PPAP, Independent Warehouse QC, and a Traceable Product Data Management System are the five elements that help us quickly fulfill your entire AQL requirements.

Projects handling can tell you a lot about capacity. We have many years’ experience in the supply of steel parts and forgings for automotive industry, investment and resin sand casting for wind energy industry, nonstandard corner casting and locking kits for container industry, impellers for aeronautical industry, and stainless steel centrifugal tubes that have significantly achieved better manufacturing realization.

You may click separate product classifications to view more details.

|